Description

Induction Aluminum Foil Sealing Machine

Description

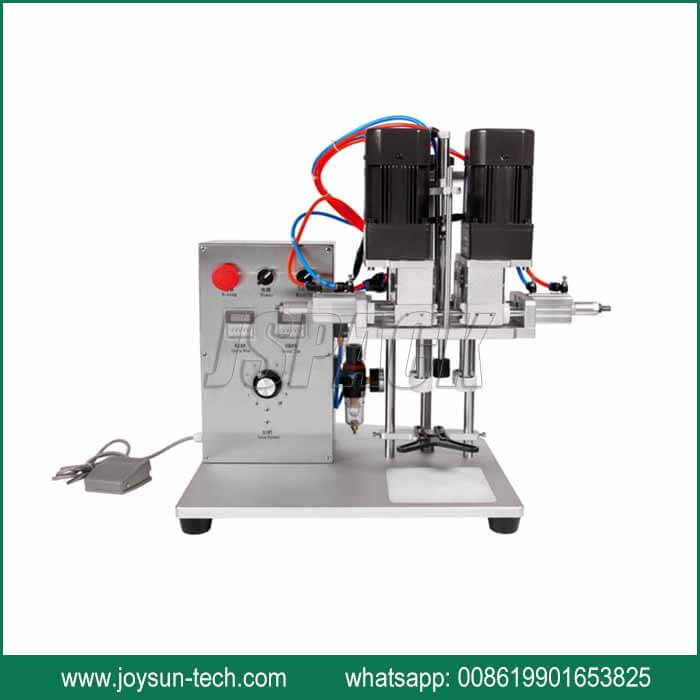

The Induction Aluminum Foil Sealing Machine is a specialized device for sealing containers using induction heating technology and aluminum foil seals. It commonly appears in industries such as food and beverage, pharmaceuticals, and chemicals. The cap sealer operates by placing an aluminum foil seal on the container’s opening and then applying an electromagnetic field through an induction coil. This field heats the foil seal, causing it to bond with the container’s neck or opening, creating an airtight and tamper-evident seal. This sealing method provides excellent protection against leakage, preserves product freshness, and ensures product integrity. The Induction Aluminum Foil Sealing Machine offers high efficiency, precise sealing control, and compatibility with a wide range of container sizes and shapes. It is a reliable solution for industries seeking secure and professional sealing of their products.

Characteristics

- The Alu Foil Cap Sealing Machine possesses several key characteristics that make it a valuable asset for various industries. Here are some typical features and characteristics of such machines:

- Suitable for containers like bottles, jars, and tubes of different sizes.

- The cap sealer automated sealing processes, minimizing the need for manual labor and ensuring high efficiency and consistency in sealing operations.

- Its temperature control mechanisms allow for precise heating of the aluminum foil caps to achieve optimal sealing conditions.

- The cap sealer offers flexibility in adjusting sealing parameters such as time, pressure, and temperature, enabling customization to suit specific product requirements.

- Fast Sealing Speed: With high-speed sealing capabilities, these cap sealers are capable of sealing a large number of containers in a short amount of time, enhancing productivity and throughput.

- Compact Design: The machines often have a compact footprint, occupying minimal space in production areas and facilitating integration into existing production lines.

- Alu Foil Cap Sealing Machines adhere to industry safety standards, incorporating safety features such as emergency stop buttons and safety interlocks to protect operators and prevent accidents.

Parameter

| Model | JSR-4000 |

| Input voltage | 220V, 50/60Hz, 1P |

| Output power KW | 0.3 |

| Induction frequency KHz | 30~100 |

| Sealing speed BPM | 0~50 |

| Sealing diameter mm | Φ20~60 or Φ50~120 |

| Operation mode | Manual (automatic) |

| Cooling mode | Water cooling |

| Weight KG | 120 |